BY STEVE CLARK / The Brownsville Herald

Article published Sunday, November 8, 2020

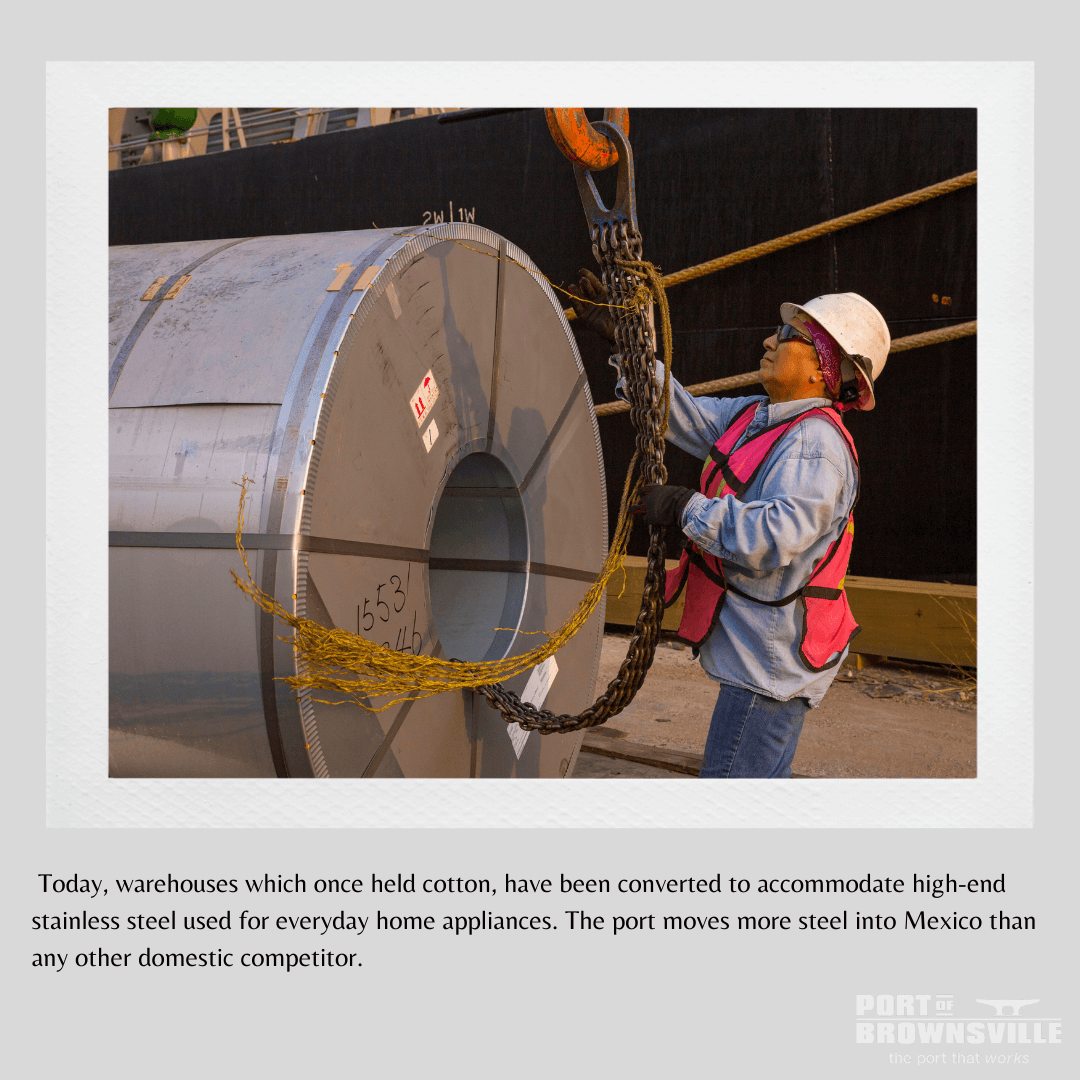

A major steel mill expansion in Nuevo Leon, Mexico, is expected to have a big impact on the Port of Brownsville as a steel importer/exporter and boost job creation locally, according to port officials.

Port Director and CEO Eduardo Campirano said the multi-billion-dollar expansion of Monterrey’s Ternium Pesqueria mill, owned by Ternium S.A., the port’s largest steel customer and the biggest steel producer in Latin America, means more steel production at the mill.

More production requires more feedstock, which means more steel slab moving through the port — most of it from a Brazilian mill also owned by Ternium, he said. The Pesqueria mill largely supplies Mexico’s automobile manufacturing sector. Ternium is headquartered in Luxembourg.

“They ship slab through the Port of Brownsville,” Campirano said. “So for us, the Pesqueria project is working in collaboration with the port, the stevedores and with (Brownsville & Rio Grande International Railway) and other parties to expand the through-put capabilities of slab through the port.”

The most slab Ternium has moved through the port in a year was about 3 million metric tons, while the expansion could mean up to 4.5 to 5 million metric tons a year, he said. Campirano said preparing for that extra activity “is going to be a lot of work.”

“There’s a possibility of maybe even looking at another crane as this volume increase,” Campirano said. “We may need to go to a fourth crane, so that may come in a year or two as we begin to ramp up.”

The port could also see bigger slabs — up to 33 metric tons each — as the Pesqueria mill’s production capacity grows, he said.

“You can see you’re talking about big volume,” Campirano said. “The railroad is going to have the available cars and the ability to move maybe two-unit trains of slab. So it just adds incrementally adds to the operation, and since there’s multiple players involved in what it takes from the time you get the slab off the vessel to deliver it to Monterrey, there’s a whole lot of pieces involved in that process.”

Preparations could also involve concrete work to sustain the movement of slab from the dock to the storage/loading area, the realignment of roads and other changes/improvements, while the port’s stevedore operations will need to invest in new equipment, he said.

“They’re going to have to provide the capability to load that (slab),” Campirano said. “The loading and unloading scheme is going to be changing. They’re probably going to be going to magnets, so that means more specialized equipment. It’s obviously going to increase the amount of equipment that the stevedores are going to have to come up with to handle that much slab.”

“It’s just that whole logistics effort, all the people who are involved to make this work — equipment operators, crane operators, truckers, you name it — it’s a big boon. It’s a plus obviously. … It’s something that we’re all working toward. And it’s something that obviously means putting people to work.”